Glass Reinforced Polyester Pipe & Fittings

Superlit is a flexible glass reinforced polyester (GRP) pipe system suitable for pressure and non pressure water supply, wastewater and industrial applications.

Superlit is a flexible glass reinforced polyester (GRP) pipe system suitable for pressure and non pressure water supply, wastewater and industrial applications.

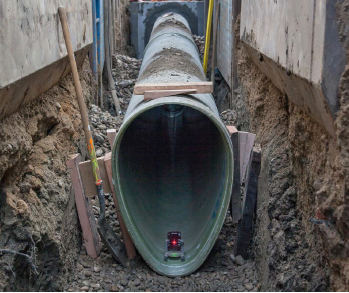

Our Glass Reinforced Polyester (GRP) jacking pipes offer high axial strength for trenchless micro-tunnelling and relining applications.

GRP manholes form an integral part of buried gravity sewage and wastewater networks, allowing surface access to the system for pipeline inspection and maintenance.

Non-circular Glass Reinforced Polyester (GRP) pipe and fittings are suited for both the trenchless rehabilitation and open-trench construction of sewage and wastewater pipelines.

GRP (Glass Reinforced Polyester) pipe provides industry-leading strength, ultra-lightweight handling and advanced corrosion resistance.

Key benefits of GRP pipe systems include:

Our GRP pipes and fittings are suitable for potable, non-potable, and industrial pipeline settings.

Typical applications for GRP pipes include:

Combining Superlit’s global expertise in composite manufacturing with our local knowledge and project support, we offer advanced GRP solutions across Australia.

Our GRP pipe systems incorporate an advanced manufacturing system that precisely optimises the distribution of glass fibres throughout the pipe wall. This industry-leading approach significantly enhances the accuracy of pipe design and enables more reliable prediction of long-term performance under different conditions.

Each layer of our GRP pipe performs a distinct and essential function. The innermost layer is composed of flexible resin, forming a sealed barrier to prevent any fluid or solid ingress into the structural core. The structural layers themselves are tailored to meet specific design pressures and stiffness requirements, while the outer surface layer protects the pipe during handling and installation and provides resistance to ultraviolet (UV) degradation.

This layered, performance-driven structure helps deliver on our commitment to precision and long-term asset reliability in our GRP pipe systems.

With over 50 years of experience, Superlit is a global manufacturer of GRP pipes, supplying critical infrastructure projects across five continents. Known for their innovation and quality, Superlit uses advanced manufacturing techniques such as Continuous Filament Winding (CFW) and Centrifugal Casting (CC) to produce pressure and non-pressure GRP pipes that meet the highest international standards.

With Clover’s deep industry expertise and unique service model, combined with Superlit’s cutting-edge technology, we provide a seamless, end-to-end service that guarantees peace of mind at every stage of your GRP pipeline project.

As our trusted partner in GRP solutions, Superlit is committed to reducing environmental impact across every stage of production. As the first GRP pipe manufacturer with an Environmental Product Declaration (EPD) verified to ISO 14025 and EN 15804, Superlit sets the benchmark for sustainability in the GRP sector.

The EPD tracks key environmental metrics including energy and water use, emissions, resource consumption and carbon footprint, providing full transparency across the product lifecycle.

By choosing our GRP pipe systems, you are selecting a high-performance pipeline solution that supports climate goals and responsible resource management without compromising on durability or quality.

Polyethelyne (PE) pipes offer durable and flexible solutions for a wide range of applications.

The PAM Zinalium® Hydroclass® and Integral® Ductile iron pipe range is a flexible pipe system suitable for pressure and non-pressure water supply, sewerage and aggressive medium applications.

Clover Resilient Seat Socket Flange Gate Valves PN16 are suitable for use in pressure and non-pressure water supply and sewerage applications.

Get in touch with our team for additional information on product pricing, technical data, project support and more.

Get in touch with our team so we can support the planning, source, and supply of your next project.

We endeavour to reply within 1 business day.

Thanks for getting in touch, we will respond as quickly as possible.

If you have an urgent matter, please call your nearest Clover branch.