Applications

Sewer Access Chambers are typically installed within gravity sewer networks to accommodate changes in pipeline diameter, changes in pipeline alignment and intersecting pipeline junctions.

Typical applications include;

- Gravity sewer mains

- Stormwater and drainage

- Buried applications

Features and Benefits

| Features | Benefits |

| Adjustable socket | The SMS Maintenance Chamber (MC) base features adjustable sockets which all the inlet and outlet pipe grade or deflection to be adjusted up to 7.5° in any direction, permitting site adjustment in the trench. |

| Light weight design | SMS Maintenance Chambers, with their modular and lightweight design, ensure safe and effortless handling without requiring heavy machinery. The components are designed for rapid installation, even in confined spaces and deep trenches, offering a significant advantage by being 90% lighter than traditional concrete options. |

| Long lasting performance | The durability of polypropylene provides the ability to resist heavy handling and installation stresses without compromising its integrity or resistance to hydrogen sulphide gas and acid sulphate soils. |

| Guaranteed Connections | SMS Maintenance Chambers feature innovative Styrene-Butadiene Rubber (SBR) or Ethylene Propylene Diene Monomer (EPDM) seals designed to meet strict Australian Standards requirements for effective sealing and resistance to root intrusion. |

| Ease of installation | The system allows for simultaneous installation with the sewer pipeline, reducing installation costs and reducing risks associated with exposed open trench excavations. |

| Eco-friendly materials and manufacturing | 100% recyclable and are noted for their low embodied energy, contributing significantly to its environmental benefits. Choosing materials with lower embodied energy helps reduce the overall carbon footprint of construction projects, aligning with sustainability goals and regulations. |

| Range of access cover options | SMS offer surface access cover solutions tailored to meet various installation needs, including both trafficable (Class D) and non-trafficable (Class B) conditions. The product range caters for diverse requirements including ‘Top Hat’ Frame and ‘Cap and Lid” options. |

Compliance

- WSA 137 “Industry standard for Un-plasticised Polyvinyl Chloride (PVC-U), Polypropylene (PP) and Polyethylene (PE) maintenance shafts, maintenance chambers and maintenance holes for sewerage”

- EN13598-2 “Plastics Piping Systems for Non-pressure Underground Drainage and Sewerage – Unplasticised Poly (Vinyl Chloride) (PVC-U), Polypropylene (PP) and Polyethylene (PE) – Part 2: Specifications for Manholes and Inspection Chambers”

- AS3996 “Access Covers and Grates”

- AS1646 “Elastomeric Seals for Waterworks Purposes”

Product Certification

The SMS Maintenance Chamber range is independently third party certified to WSA137 “Industry standard for Un-plasticised Polyvinyl Chloride (PVC-U), Polypropylene (PP) and Polyethylene (PE) maintenance shafts, maintenance chambers and maintenance holes for sewerage”

Accreditation body: Global-Mark

Product Licence Number – 695C406014802DCCC125881500313273

WSAA Product Appraisal

The SMS Maintenance Chamber range is independently appraised and recommended by the Water Services Association of Australia (WSAA);

- Product Appraisal PA13/17

WSAA Product Specification(s)

These products comply with the requirements of the following Water Services Association of Australia (WSAA) purchase specification(s);

- WSA PS-337 Maintenance Chambers (MC) – Polypropylene (PP) for Non-Pressure Applications – Gravity Sewerage

- WSA PS–290 Access Covers and Frames for Water Supply and Sewerage to WSA 132

Compatible pipe types and diameters

These products are compatible with smooth wall DWV unplasticised PVC pipe (U-PVC) in the following diameters;

- DN150 (160mm OD)

- DN225 (250mm OD)

- DN300 (315mm OD)

- DN375 (400mm OD)

Flow Profiles

- 180° (Straight)

- 150°

- 120°

- 90°

- 4 Way 90° Cross (Double Sweep)

- Tee

Installation depth

These products can be installed to a maximum depth of 6 metres and a minimum depth of 1m (subject to local authority approval).

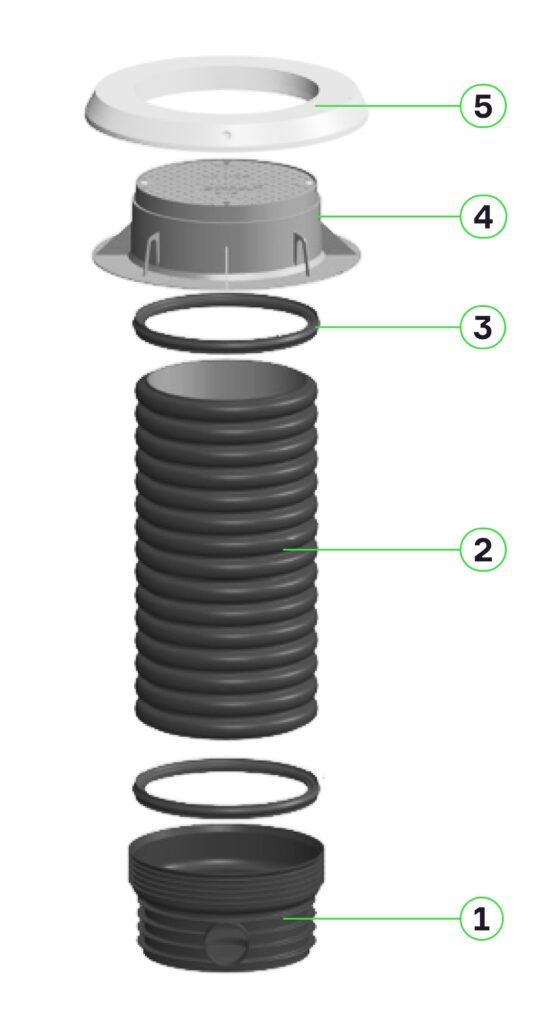

Components

| Item | Part Name | Material |

| 1 | Base | Polypropylene |

| 2 | Riser | Polypropylene or Polyethylene |

| 3 | Gasket | SBR (Styrene Butadiene Rubber) or EPDM (Ethylene Propylene Diene Monomer) |

| 4 | Access Cover & Frame | Ductile Iron |

| 5 | Vegetation Ring | Concrete or recycled plastic |

Installation

Installation methods are generally in accordance with AS/NZS2566.2 “Buried flexible pipelines – Installation”. The standard specifies the requirements for the installation of buried flexible pipelines with structural design in accordance with AS/NZS2566.1 “Buried flexible pipelines – Design” and local authority requirements.

Testing & Commissioning

Testing and commissioning methods are generally in accordance with AS/NZS2566.2 “Buried flexible pipelines – Installation”. The standard specifies the requirements for the field-testing and commissioning of buried flexible pipelines with structural design in accordance with AS/NZS2566.1 “Buried flexible pipelines – Design” and local authority requirements.

Installation Training

Clover’s in-house engineering team provides a range of training, accreditation and technical support services.

The Clover Academy installation training course provides installers with important information relating to the correct handling, installation, testing, maintenance and repair of Clover pipe systems and products.

Contact the Clover engineering team to discuss scheduling a training program.

Technical Support

Clover’s in-house engineering team combines specialist technical knowledge, creative thinking and on-the-job experience, to offer our clients a range of project planning and consultation services.

From recommendations on product innovations, to crafting complex end-to-end solutions, our collaborative approach bridges the gap between contractors, authorities and suppliers. The only Australian provider able to offer clients the full product suite, Clover offers unbiased, strategic insights that always consider the bigger picture.

From initial planning, to onsite training and technical assistance, we offer input across every stage of your project’s timeline. Our contribution continues beyond the project design, and we remain accessible for ongoing changes and developments over the course of each project.

We work with contractors, asset managers, local councils and government, developers and other pipeline professionals to specify bespoke product solutions. By engaging our team of engineers, you gain access to unparalleled product knowledge and expertise.

Life Expectancy

When installed and operated in accordance with the manufacturers guidelines this pipe system can be expected to perform well in excess of 100 years before major rehabilitation is required.