Ductile Iron Pipe | DN100 ‑ DN750

The PAM Zinalium® Hydroclass® and Integral® Ductile iron pipe range is a flexible pipe system suitable for pressure and non-pressure water supply, sewerage and aggressive medium applications.

The PAM Zinalium® Hydroclass® and Integral® Ductile iron pipe range is a flexible pipe system suitable for pressure and non-pressure water supply, sewerage and aggressive medium applications.

The PAM Zinalium® Hydroclass® and Integral® large diameter ductile iron pipe range is a flexible pipe system suitable for pressure and non-pressure water supply, sewerage and aggressive medium applications.

Our range of ductile iron fittings offer durability and strength for long-term performance across a range of water, sewage, wastewater and slurry applications.

Engineered with ductile cast iron, ductile iron pipe is a durable and flexible solution for water and wastewater systems.

Key benefits of ductile iron pipe systems include:

Our ductile iron pipe systems are suitable for both pressure and non-pressure applications and can be installed buried or above ground.

Typical applications for ductile iron pipes include:

As a future-ready solution our customers can count on, ductile iron supports our mission to build smarter, stronger water infrastructure.

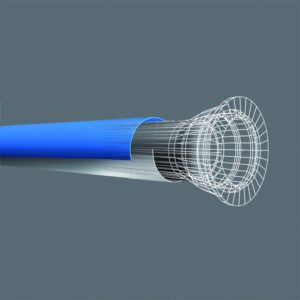

Zinalium-coated ductile iron pipe features a three-part protective system: the pipe itself, a Zinalium alloy coating and a synthetic resin pore sealer.

The Zinalium coating is made from 85% zinc and 15% aluminium, melted onto the as-cast surface at high pressure. This alloy creates a uniform microstructure that maximises the corrosion resistance of the zinc. It’s applied at a minimum thickness of 400g/m².

To enhance durability, a synthetic epoxy pore sealer is applied over the coating at 100μm. This controls how the zinc is exposed to the soil. Without this layer on the ductile iron pipe, the protective properties of the Zinalium coating could wash away, reducing long-term protection.

We’re proud to be the exclusive Australian distributor of Saint-Gobain PAM, a global leader in ductile iron pipeline systems. Founded in 1856, Saint-Gobain PAM combines over 165 years of engineering expertise.

Together, we deliver high-performance ductile iron pipe solutions, including the advanced Zinalium-coated Hydroclass range: designed for long-term resilience in water, wastewater and aggressive soil applications.

Combining Saint-Gobain PAM’s patented technologies and global manufacturing strength with Clover’s industry-leading service offering and expertise, we offer Australia’s most trusted ductile iron systems.

Ductile iron pipes meet the needs of those seeking to balance environmental responsibility with long-term asset performance. Our partner, Saint-Gobain PAM, applies Life Cycle Analysis (LCA) and Total Cost of Ownership (TCO) assessments to help quantify sustainability outcomes across the entire pipeline lifespan, from manufacturing to installation, operation and eventual recycling.

Ductile iron is 100% recyclable at end-of-life, delivering a long service life (often 100+ years) with minimal maintenance. With fewer disruptions to a pipeline’s serviceability over time, ductile iron pipe systems are an industry-leading choice across a range of applications.

Our range of unrestrained mechanical couplings comply with AS/NSZ 4998 for potable and non-potable water applications.

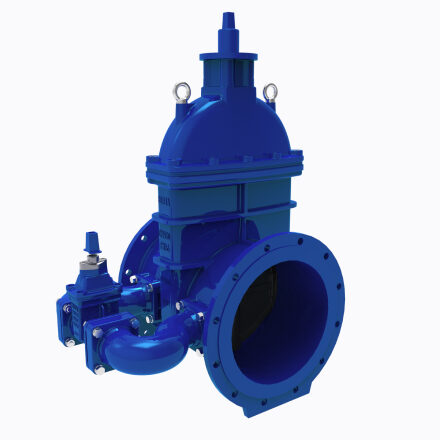

Clover Resilient Seat Double Flange Integral Bypass Gate Valves PN16 are suitable for use in pressure and non-pressure water supply and sewerage applications.

Superlit is a flexible glass reinforced polyester (GRP) pipe system suitable for pressure and non pressure water supply, wastewater and industrial applications.

Get in touch with our team for additional information on product pricing, technical data, project support and more.

Get in touch with our team so we can support the planning, source, and supply of your next project.

We endeavour to reply within 1 business day.

Thanks for getting in touch, we will respond as quickly as possible.

If you have an urgent matter, please call your nearest Clover branch.