Glass Reinforced Polyester Pipe & Fittings

Superlit is a flexible glass reinforced polyester (GRP) pipe system suitable for pressure and non pressure water supply, wastewater and industrial applications.

Celebrating 10 years of operations.

Read about our journey.

Superlit is a flexible glass reinforced polyester (GRP) pipe system suitable for pressure and non pressure water supply, wastewater and industrial applications.

Our Glass Reinforced Polyester (GRP) jacking pipes offer high axial strength for trenchless micro-tunnelling and relining applications.

GRP manholes form an integral part of buried gravity sewage and wastewater networks, allowing surface access to the system for pipeline inspection and maintenance.

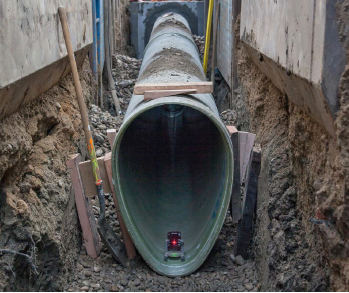

Non-circular Glass Reinforced Polyester (GRP) pipe and fittings are suited for both the trenchless rehabilitation and open-trench construction of sewage and wastewater pipelines.

Get in touch with our team for additional information on product pricing, technical data, project support and more.

Get in touch with our team so we can support the planning, source, and supply of your next project.

We endeavour to reply within 1 business day.

Thanks for getting in touch, we will respond as quickly as possible.

If you have an urgent matter, please call your nearest Clover branch.